The ECR-Ortho

I started this project because I have owned the Sony ECR-500 system a few times in my life and enjoyed their sound reproduction and character a lot (especially as it pertains to Marta Gomez's voice like whoa!). I also got into planar magnetic headphones because of Head-Fi member Wualta (and others who helped spur on the creation of the Orthodynamic Roundup thread) and really enjoyed what planar magnetic headphones have to offer. I decided I wanted to create a headphone that for all intents and purposes would sound and behave exactly like the ECR-500, but not require an energizer box to be driven to audible levels. I've since changed the goal of the project to creating the Crop Circle Audio forum which is, in and of itself, an entirely different beast. The CCA-1 (which isn't even a solid idea yet, although I'd like it to be a planar magnetic headphone with a pentagonal diaphragm and spiral circuit of some kind) is also quite different from what I originally set out to design with the ECR-Ortho. That being said, here are some pictures I've taken along the way as I've discovered more about this hobby and what it is I'm actually doing with my life:

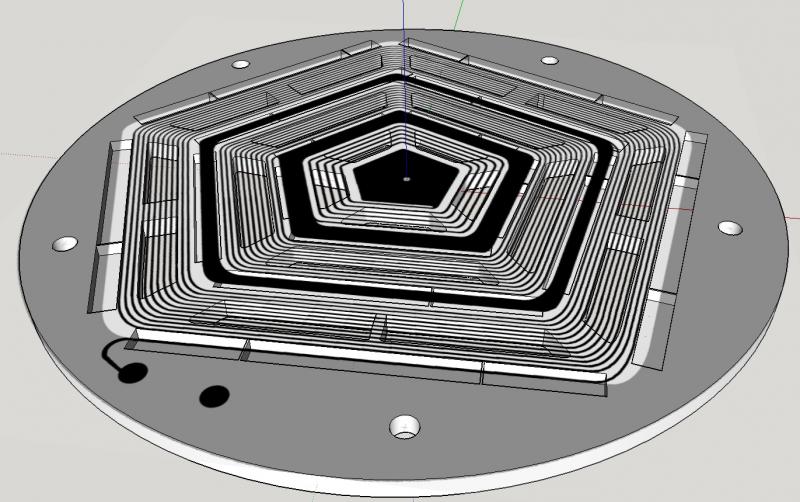

This is a picture of an .stl file I created in Google Sketchup. It's a magnet assembly for the ECR-Ortho project that's based off a spiral conductor. The magnet assembly is sized to fit in a Denon AH-D2000 frame.

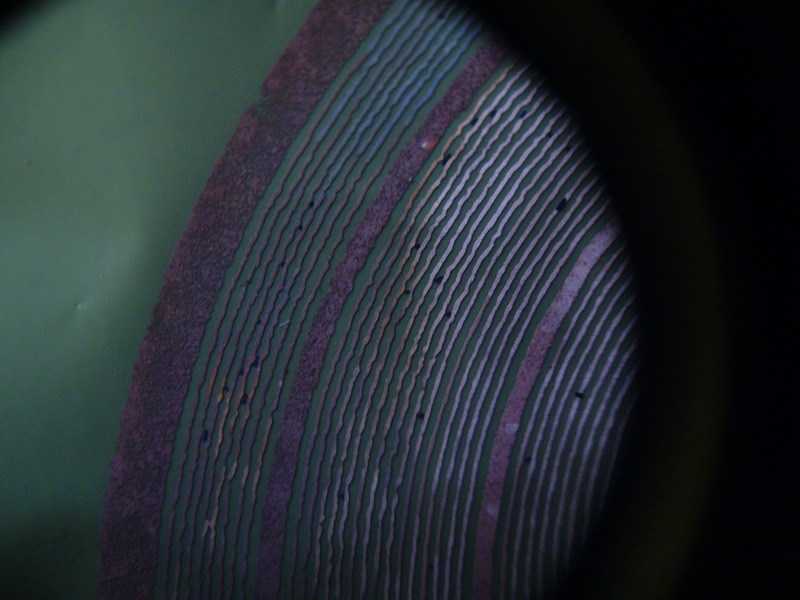

Here's a picture of some preliminary photo-mask printing that I dabbled in. As you can see this circuit design is serpentine, not spiral.

Here is a picture of rosin powder melted into inkjet ink printed in the form of a pentagonal spiral circuit. I was practicing on transparency hoping I'd eventually be able to use rosin powder as an etch resist.

http://www.thingiverse.com/thing:341212

That is a link to a thingiverse that I made which was rather unsuccessful up to this point. It is related to the CCA-1, but not quite it exactly.

But what is it?

The ECR-Ortho project is a dream to build -primarily via computer numerical control (or CNC) technology such as 3D printing, laser cutting, etc. in order to keep manufacturing costs down- open source headphones that can be disassembled by hand (no tools needed, no screws, etc. everything snaps together) which employ planar magnetic drivers inspired by the Sony ECR lineup of headphones. I'd currently like the circuit to be spiral, however, I believe a serpentine circuit will be easier to manufacture and implement. I'd also like to explore diaphragm material options such as Mylar, Kapton, and even elastomer-thermoplastic mixtures not too dissimilar from the urethane diaphragms found in the Micro Seiki MX-1, or AMFITON TDS-15.

So how do I make a diaphragm?

I'm not exactly sure how we should go about mass producing these for ourselves, but I can share with you my experiences.

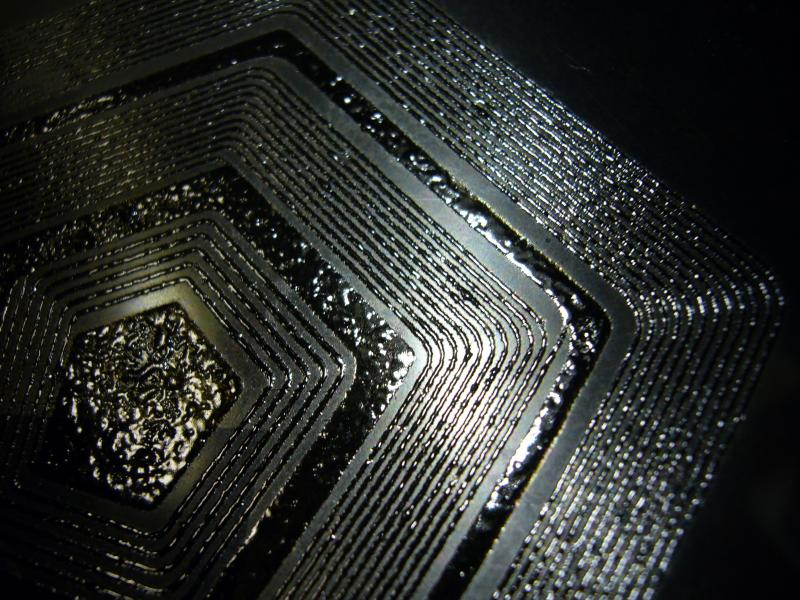

I scanned a Bang & Olufsen U70 diaphragm and it looked great, but when I zoomed in on it it looked like a garbled up bunch of gobbledygook. I spent hours attempting to transform what was gobbledygook into a perfect Black and White image in http://www.gimp.org/. I then printed it with an old HP Laser printer onto Dupont Pyralux (Copper clad Kapton), dunked the printed image into an acid bath of Muriatic Acid (HCl), Hydrogen Peroxide (H2O2), and table salt (NaCl) and got stuff that looked like these images:

Preliminary testing:

Here you can see how the circuit is cleaner towards the center. It's because I never fully finished painting the U70 driver in Gimp. The penny is for scale and the picture was taken through a loupe given to me for free by a man named Hi.

Another for good measure. I've since gotten a better camera, so in the future if I experiment I should be able to pull off some better shots.

Now, while these results look promising, I'm not sure I was using the correct acid. The fumes that were given off during etching smelled horrendous and breathing it in felt like it could melt your throat. BE CAREFUL!

You can check out some instructables such as http://www.instructables.com/id/Is-the-best-PCB-etchant-in-every-kitchen-/ if you're concerned about using strong chemicals, but your etch times will be impacted, as will the cleanliness of your etches.

3D printing!

Here are the first set of 3D printed ECR-Ortho magnet assemblies. I went to 3dhubs.com and found someone (I'm sorry, I forgot your name and can't find it in my 3dhub history) who was somewhat local. The notches on the Black piece match up with the Denon AH-D2000 baffle so they could potentially be screwed into place.

The resolution capabilities of the 3D printer that was used to print these pieces wasn't quite where I needed it to be, I think. The magnet you see in the photo below should be flush and most of the slots are too tight to even fit a magnet, I just got lucky this one could squeeze his way in for a photo. I'm not sure what happened. Did I miscalculate the width that the slots needed to be? Did I need to give the magnets a little breathing room with my calculations so that they'd slide in better? Is it the printer? Who knows?

You can see the magnets are on the thin side. Efficiency will suffer, but I wanted to keep the overall profile of the driver down.

Why aren't these headphones in my hands already?!

https://cropcircleaudio.board-directory.net/t5-chi-raq-the-movie-systemic-inequality-in-englewood

What next?

http://www.thingiverse.com/thing:1411538/#files

Okay, I made a new thingiverse. Files are in .stl format and ready for download, as is the spacer file (in .skp) and the circuit (in .xcf meant to be opened in Gimp).

There are three sizes of magnets used in this build, however, I'm unsure on the quantity. If you're attempting to populate the magnet assemblies with magnets check the .stl files and count, it should be easy since there's just small, medium, and large.

Small:1/4" x 1/8" x 1/16"

Medium: 1/2" x 1/8" x 1/16"

Large: 1" x 1/8" x 1/16"

The only problem I can foresee with using PLA as our magnet assembly material is the fact that it's so brittle. If you try to screw into PLA I'm afraid it'd just just chip/crack. This means we'd have to epoxy or otherwise glue the drivers into the D2000 frame which isn't the most user-friendly, but can be dealt with. Let me know what you think as I don't have much/any experience with oriented PLA objects. If push comes to shove we could always print in PLA, cast mold the print, and then make duplicates in whatever epoxy resin we want. If we can find someone with a highly detailed ABS printer who has a lot of experience, though, this is even better, imo.